History Of Precast Concrete Conduit

As early as 200 BC the ancient Romans used it to build aqueducts to distribute water throughout their cities. Ironically today a company named Roman Stone is using it to manufacture conduit to carry electrical current to millions of consumers. "It" is concrete and thanks to improvements in extrusion technology, "concrete conduit" has again flourished as the most cost-effective means of transmission available. How can we make this claim? First we need to tell you a little more about the concept of this unconventional product that we aptly call "Concrete Conduit”.

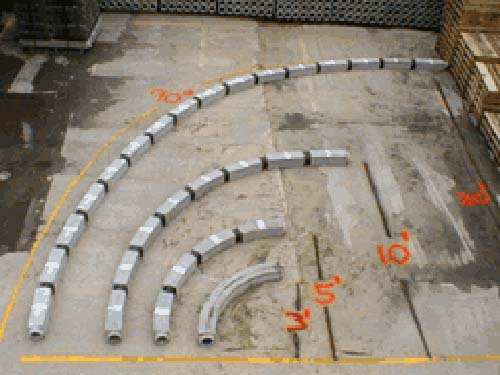

Think of an underground power network with dozens of cables traveling for miles. Each line must be protected, yet segregated from one another. Now picture for a moment a honeycomb pattern with all its many cavities. That is what concrete conduit looks like when stacked in a trench. Put the two together and you have the perfect medium for which cable can traverse. There is no better environment for electrical current than non-conductive, heat dissipating concrete duct. "Okay, how is concrete conduit installed?" To answer that question we will need to describe what a length of conduit looks like. Square on the outside, and round on the inside and 4 feet at its longest length, this unique shape allows sections to be stacked on one another. Once the desired trench is excavated, sections are connected easily by plastic couplings that are attached to specially formed ends. Contractors can use any one of a series of configurations to create their own custom "duct bank". The removed earth, if clean, is then back-filled into the open trench.

Think about it. Gone is the more time consuming and labor intensive process of laying conventional conduit that must be braced and then encapsulated in concrete. No waiting for a ready mix truck, no need for forms, no worry over pipe moving. The result: less time, effort and materials.

Add to that the fact that if any one cable should experience a "burnout", the replacement process is drastically reduced. No longer does the entire area have to be retrenched to expose the suspected line. Since the integrity of the adjoining pipe is not affected, the problem is isolated to one small section. Workmen have only to pull out the damaged line and clear out any debris from the opening with an inline broom mechanism and then simply pull a new cable through. The unaltered walls of surrounding pipe continue to afford a viable tunnel for the new line. No need to lay new pipe, no disturbance to the ground above.

Roman Stone Construction is proud of the over half century relationship it has enjoyed with one of the world's largest electrical utilities. Consolidated Edison of New York, unequaled in its demand for electrical distribution products, has installed millions of feet of concrete conduit since the early 40's. We can think of no higher recommendation than the one that comes from the distinct privilege we have in servicing their needs. In fact, their Materials Management section is always ready to share information with their counterparts throughout the country concerning this type of duct.

Click to Download CON EDISON NUMERICAL INDEX CONCRETE CONDUIT - UPDATED 01.18.18